Products

| Product Name: Water control valves Product Introduction: Hydraulic control valves are imported from Taiwan to China late nineties, the earliest use in some countries, the agricultural irrigation systems, mass production in Israel, the Netherlands, Denmark and other European countries, and later developed into the United States, Canada and Asia and other places, and in the Xu things outside the field in addition to irrigation has been widely used and developed. I produced a series of wide hydraulic control valve well in domestic and foreign construction, fire, municipal, power, pipeline and other systems have performance. |

Application Standard

Quality assurance: ISO9001

Test Standard: GB / T 13927 API598

Flange Standard: GB / T 17241.6 GB / T 9113.1

Design: JB / T 10674

Performance range

| (Mpa) | 1.0 | 1.6 | 2.5 |

| (Mpa) | 1.5 | 2.4 | 3.75 |

| (Mpa) | 1.1 | 1.76 | 2.75 |

| (Bar) | 6 | 0.6 | 6 |

| Working temperature | <80℃ | ||

| For media | Water and physical and chemical properties similar to water media Germany | ||

The main parts of the material

| NO . | diaphragm | & nbsp; | Piston |

| 1 choice of material Branch | Part Name | Selection of materials | Part Name |

| 2 gray iron, ductile iron, carbon steel, stainless steel | bonnet | gray iron, ductile iron, carbon steel, stainless steel | bonnet |

| 3 spring steel, stainless steel | Spring | stainless steel | liner |

| 4 gray iron, ductile iron, carbon steel, stainless steel | diaphragm plate | Ductile | Pistons |

| 5 nylon reinforced nitrile rubber, nylon reinforced EPDM rubber | patch | nitrile rubber, EPDM | ring |

| 6 2Cr13 | Stem | 2Crl3 | Stem |

| 7 gray iron, ductile iron, carbon steel, copper, stainless steel | disc | spring steel, stainless steel | Spring |

| 8 nitrile rubber, EPDM | 0-ring | Ductile | disc |

| 9 gray iron, ductile iron, carbon steel, stainless steel | 0-ring plate | nitrile rubber, EPDM | seal |

| 10 copper alloy plate, stainless steel | Seat | copper alloy plate, stainless steel | Seat |

| 11 gray iron, ductile iron, carbon steel, stainless steel | body | Ductile | sealing plate |

| cast iron, ductile iron, steel | body |

Advantages and features

★ body with full channel, streamlined design, fluid resistance, large flow.

★ body, head, piston-cylinder connection by double gasket and sealing ring seal, no leakage.

★ body, piston cylinder, piston double-oriented, smooth motion, and reliable.

★ All stainless steel piston cylinder, the whole cast piston, NBR sealing ring, the perfect combination of greatly extended service life.

★ introduction of foreign advanced technology, removable seat structure ingenious, innovative ideas, easy maintenance and replacement painting

★ bring back the piston cylinder bore, due to increase damping piston movement will have to become more stable.

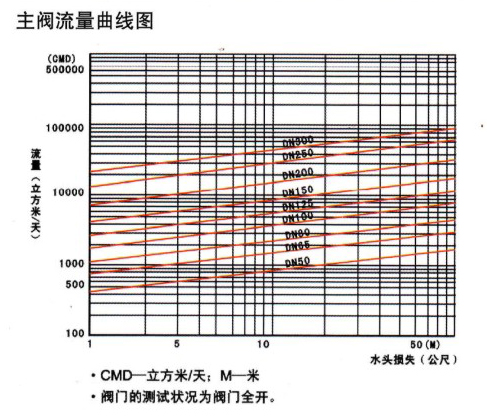

The main valve flow graph

CMD一立方米/;M一米

阀门的测试状况为阀门全开。

密封垫和密封环双重密封

阀盖与阀体上的内凹槽通过活塞缸的外固定位,确保阀盘、活塞、指示杆同心,使阀盘运动自如,从而提高主阀的灵敏度,即使在流量或压力波动不大的倩况下,活塞式水力控制阀亦能可靠地工作。为了达到阀体、阀盖、活塞缸连接处无外漏,在活塞缸上面与阀盖连接面和活塞缸下面与阀体连接处分别采用弹性垫片和NBR密封环密封。

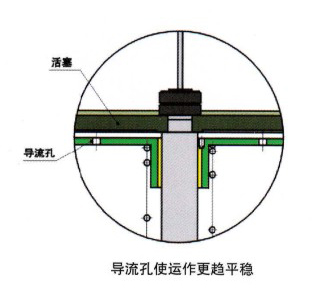

导流孔使运作更趋于平稳

为了使阀盘上下产生压差,活塞的面积必须大于阀盘的面积,这样在大口径的阀门中活塞面积很大,运作平稳性较差。我们在活塞缸的底部设计了导流孔结构,适当地增加阀盘运动的阻尼,使阀盘的运动更趋于平稳,从而提高阀门的可靠性,减少故障的发生。导流孔均匀分布在活塞缸的底平面上,并视阀门口径的大小决定导流孔的数量和尺寸。

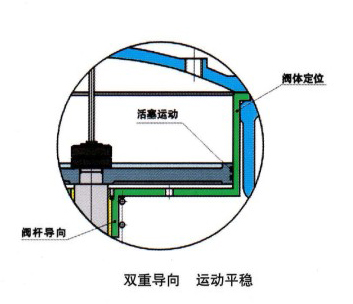

双重导向 运动平稳

阀体颈部有一定宽度的加工面,与不锈钢活塞缸的外圆配合,使得活塞缸在阀体内平稳固定,带有两道密封圈的活塞在经过行磨的活塞缸内璧作上下运动,同时活塞缸下端设计成带铜衬套的导向孔,形成双重导向,即使口径再大的阀门也能确保其运动自如、平稳,从而提高使用寿命和安全可靠性。